How many salt spray tests on coatings are there?

What are their characteristics?

Is there a relationship for predicting how many years a component will work starting from the duration of an accelerated test?

Salt spray tests on coatings are accelerated corrosion tests which can be divided into two main classes: constant and cyclic climate tests. This article will describe the most popular tests belonging to the first class, namely those performed under constant conditions. Considering the relevant number of international standards and specifications, this list is not intended to be complete.

Accelerated corrosion tests

A long-term service life is simulated by a number of accelerated corrosion tests, in order to assess the effect of corrosion in a time lapse. Even though the simulation offered by accelerated corrosion tests provides limited description of the complex reality, standards and regulations developed by far are commonly considered a useful tool for industrial activities to manufacture reliable and performant products.

Salt spray

The salt spray test provides data on the corrosion resistance of coated work pieces in general. The coating is scratched with a defined tool (scribe mark) and subjected to salt fog from a solution that contains 50 g/l sodium chloride (NaCl) at the temperature of 35°C. Steel substrates are usually tested in a neutral salt fog (ISO 9227 NSS, ASTM B117, EN 13523-8), while aluminium (Al) is subjected to an atmosphere that is additionally acidulated with acetic acid (ISO 9227 AASS). In some cases, e.g. automotive applications like wheels, this is even enhanced by adding copper chloride (ISO 9227 CASS). Test specimens are removed from the test chamber after the agreed time (typically 2 to 6 weeks) and inspected for blistering and adhesion loss (creepage) progressing from the scribe and, when applicable, from cut edges.

Constant climate, humidity

For constant climate testing, coated specimens are scribe-marked and may be bent or deformed in another way. After storage in a test compartment under constant humidity and temperature, they are inspected regarding blistering and other apparent visual changes.

Condensation

The condensation test is focused on the resistance of coatings under elevated temperature and permanent humidity. Specimens are stored at 100% RH and 40°C, and then checked for blisters and visible deterioration (ISO 6270-1 and 2).

Boiling, water soak

Water soak tests usually comprise immersion in deionised water at 40°C, however may be extended to boiling. In case of sheet material, it is usual to apply a deformation by bending or cupping. Test specimens are checked for blisters and other visual changes, as well as for adhesion (by taping), if applicable, in deformed areas. Test times range from 15 min to several hours and are subject to agreement.

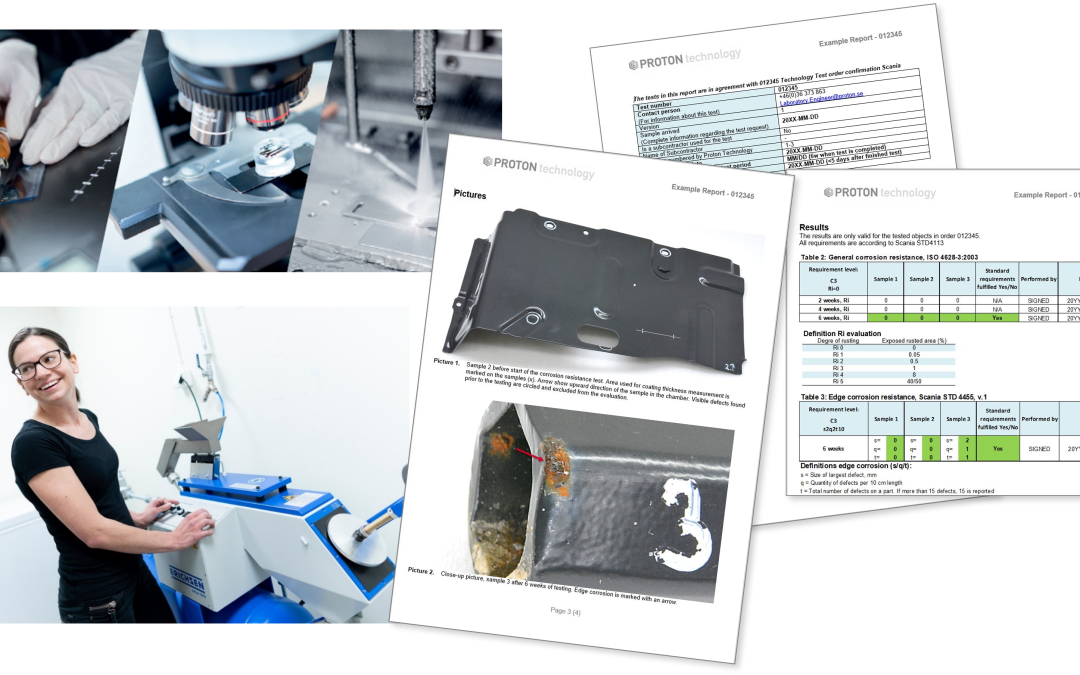

What salt spray testing on coatings can we perform?

The complete salt spray test list that we make available to the customers can be downloaded from the following link and it includes more than 200 corrosion test methods in accordance with international standards and specifications of several manufacturers like Scania, Volvo, Volvo Cars, Ford, MAN, Volkswagen, Jaguar, Land-Rover, Daimler, IKEA and Husqvarna.

Do you need further information?

Contact us by phone: +39 351 723 9441 or e-mail: material@materialscan.it.